Note: This is an ongoing project that will be updated as significant progress is made in the future

Project Overview

Worcester Polytechnic Institute has a combat robotics club that primarily competes in the 3 lb category, otherwise known as Beetleweight. However, an unexplored territory that the team has explored has been the Full-Combat Antweight class. This is partially due to the main focus being the Beetleweight weight class of combat robotics

This weight class of combat robots is primarily hosted in western Massachusetts and New Jersey. Since May 2025 I have been designing and competing with my own Full-Combat Antweight called Red Hawk.

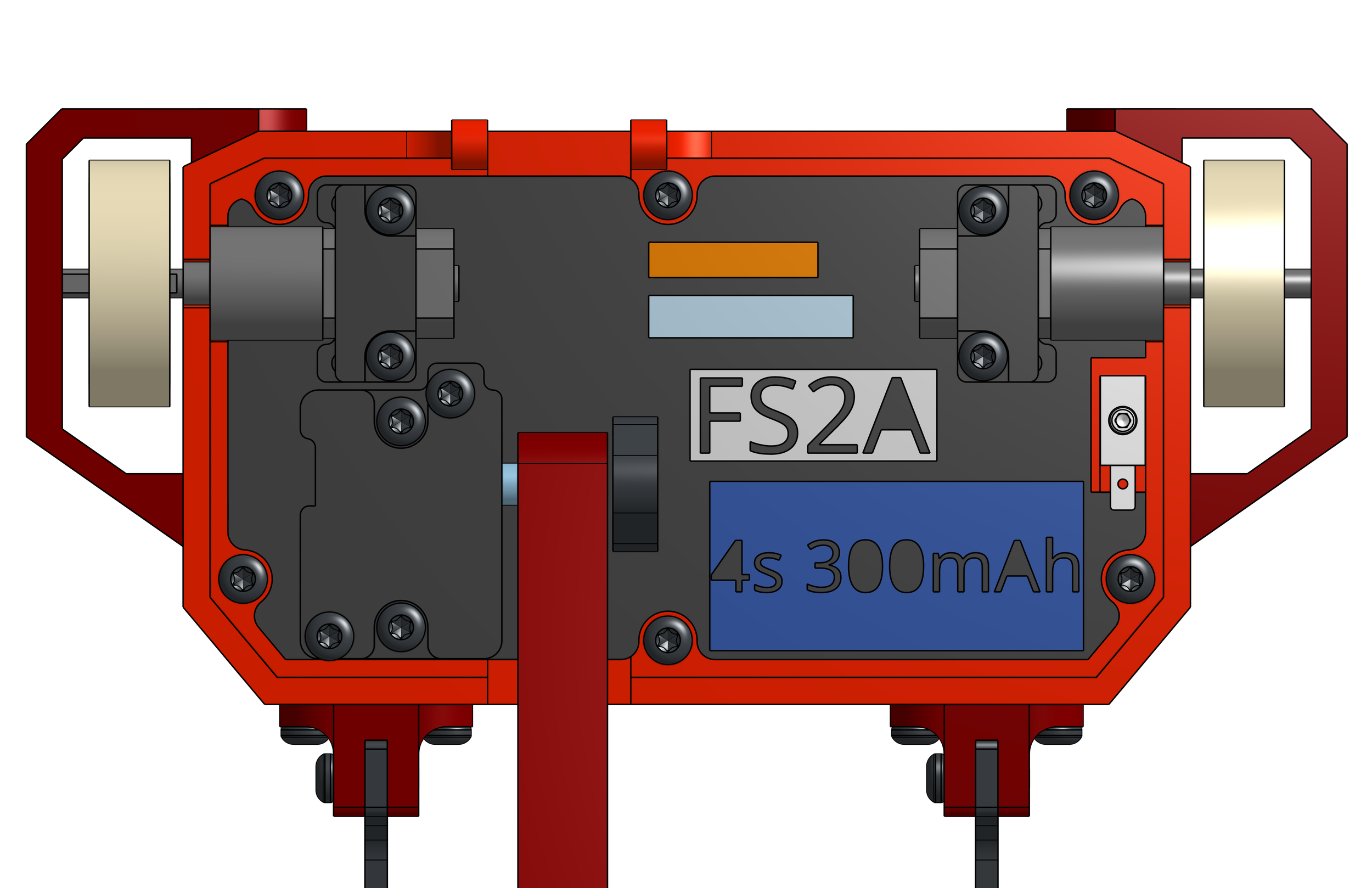

Red Hawk is a 2-wheel drive robot that uses a motor-driven arm to deliver overhead attacks on opponents with a directly driven saw blade. This form of attack is really powerful, as most robots don’t have the weight on the top and bottom of their robots for steels that can withstand overhead attacks.

The body of Red Hawk’s chassis is made out of TPU, a flexible 3D printing filament that is strong due to its elastic properties. There are carbon fiber plates at the top and bottom of the chassis that stiffens the TPU body, making it very strong.

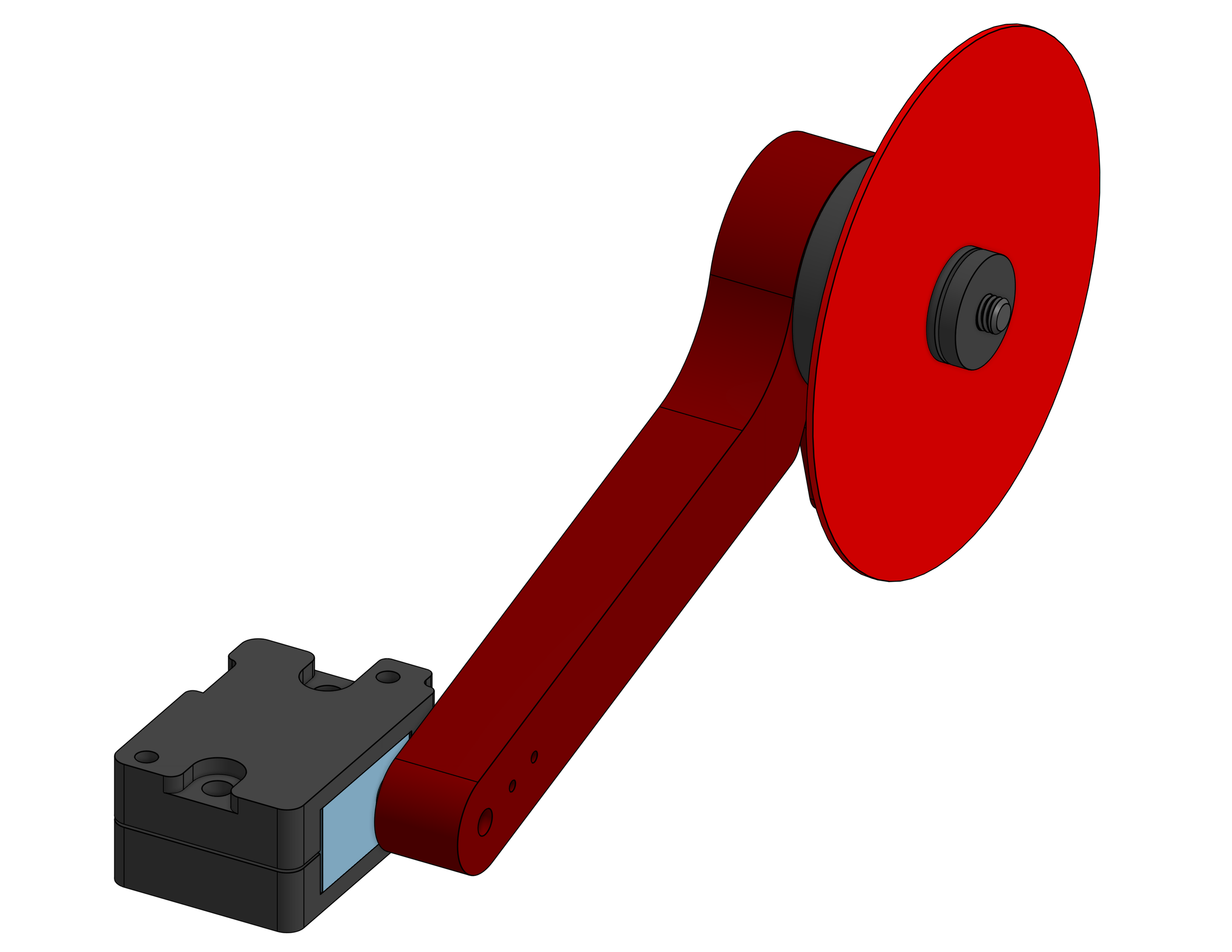

The weapon arm of the robot is driven by a 7 kg-cm servo motor. After extensive research of torque:motor size ratio’s for servo’s, I found a servo at this scale to be the right option

Alongside the chassis, the weapon arm is also made out of TPU. The reasoning behind this is for the arm to absorb the shock of the weapon saw contacting my opponent, as TPU is rubbery in nature. The weapon blade for Version 1 of Red Hawk was a off-cut blade that I found off of Amazon.

V1 Competition Results

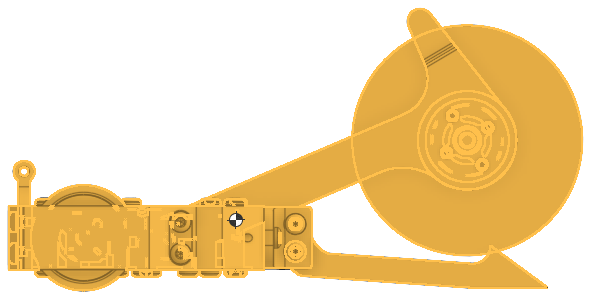

In late September of 2025, Red Hawk competed in a local Antweight competition that was run in Fitchburg, MA. This was the same venue that Thimbleberry first debuted in September of 2024. Unlike Thimbleberry, Red Hawk was able to compete in 3 rounds, going 1-2 and sustaining zero significant damage. I was even able to successfully cut through an opponent’s top plate one match!

Photo taken by Geoffrey Edge

Version 2 Revisions

After going through the first design cycle of Red Hawk, there were many aspects of the robot that I could greatly improve. A lot of changes came from the way I distributed the mass of the robot, as well as more configurations for different matchups.

Here are some of the major configurations I have made. Each version has their own strong and weak matchups to go up against

Standard Configuration

This is the standard configuration that I use against common robot archetypes like vertical spinners and drum spinners. This configuration uses AR500 Steel Forks that maximizes grounding against my opponent

Anti-Horizontal Configuration

This is the configuration I use against robots that use horizontal spinning weapons. It uses a titanium wedge that serves as a substitute to the steel forks, which would have faced some major bends in these matchups

Anti-Overhead Configuration

This is the configuration I use against robots that use overhead attacks similar to mine. For this config, I am utilizing 1075 Spring Steel top plates instead of Carbon Fiber. I also am using TPU 3D Printed Baleen Forks. These serve as a way to catch my opponent, while providing the weight I need to run heavier top armor.