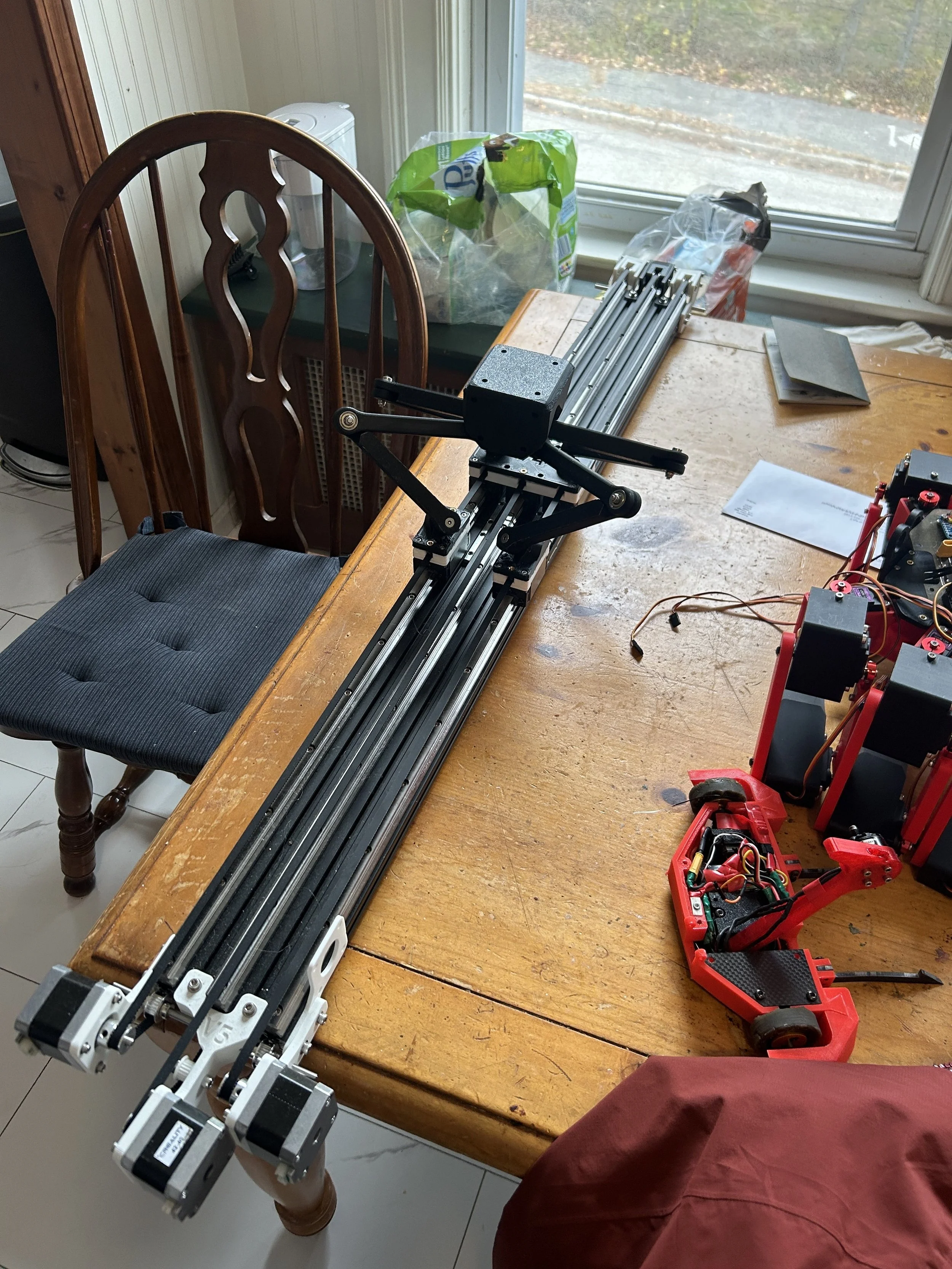

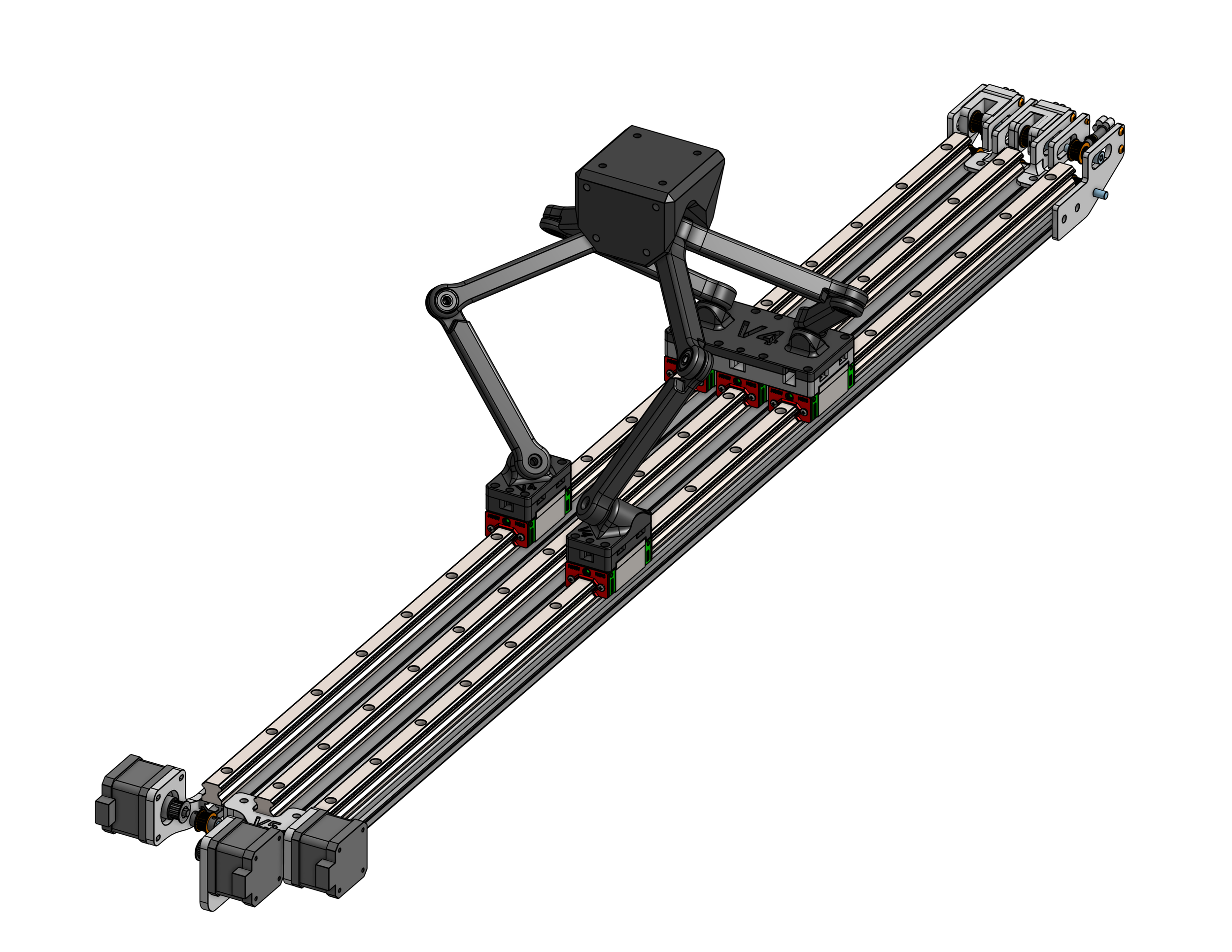

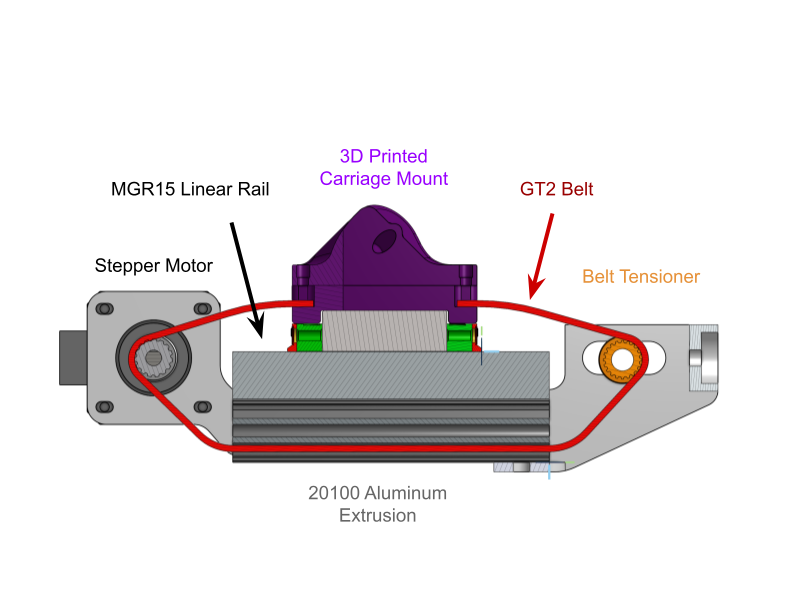

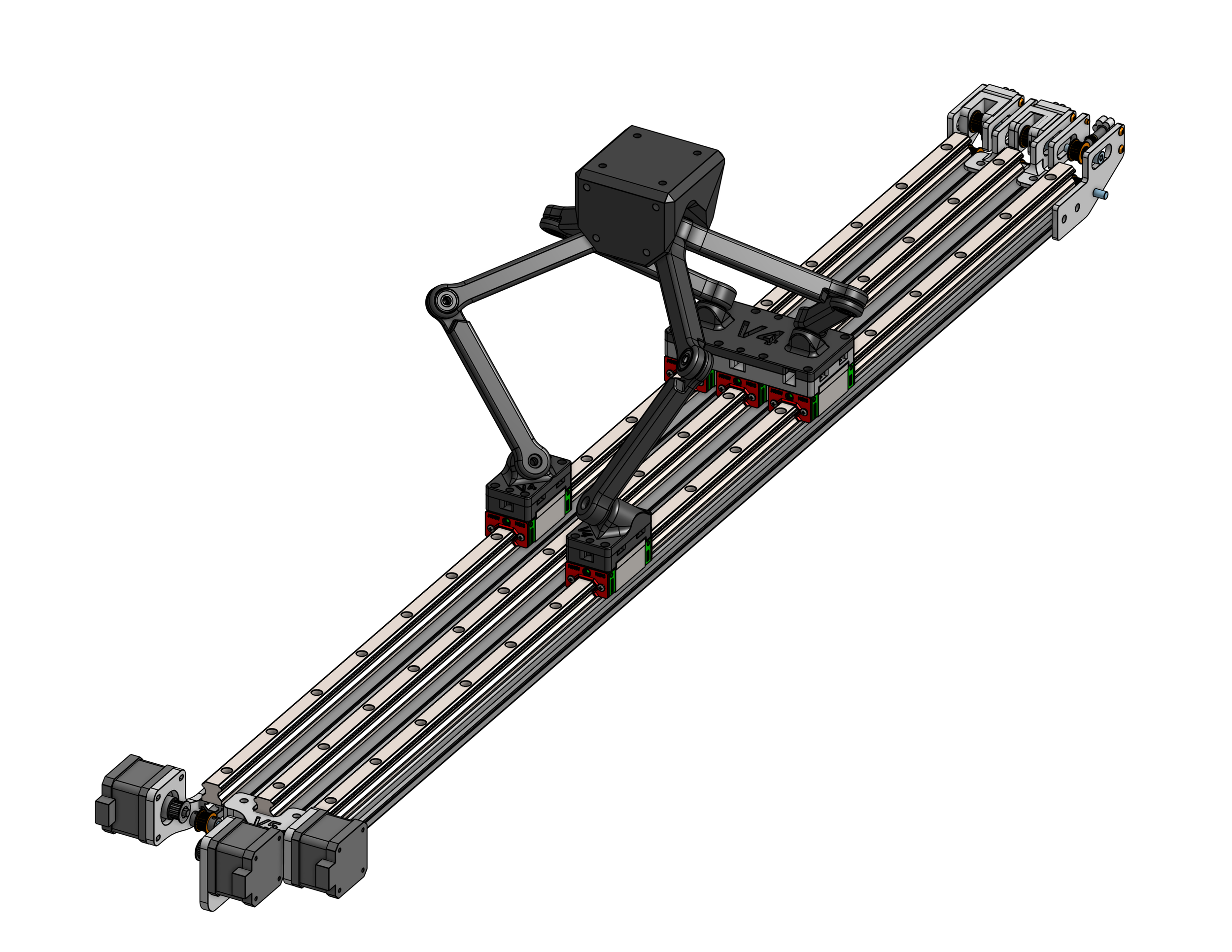

Project Overview

Since the summer of 2025, me and one of my colleagues have been developing and researching out take on a Parallel-Axis Tripteron. Through this project, we are experiencing a WPI-specific program called an Independent Study. This program has allowed me and my colleague to learn about linkage analysis from WPI professor Mustapha S. Fofana.

By the end of this project, we hope to accomplish a fully iterated version of the prototype we built during summertime, alongside gaining a mastery of linkages.