Note: This is an ongoing project that will be updated as significant progress is made in the future

Project Overview

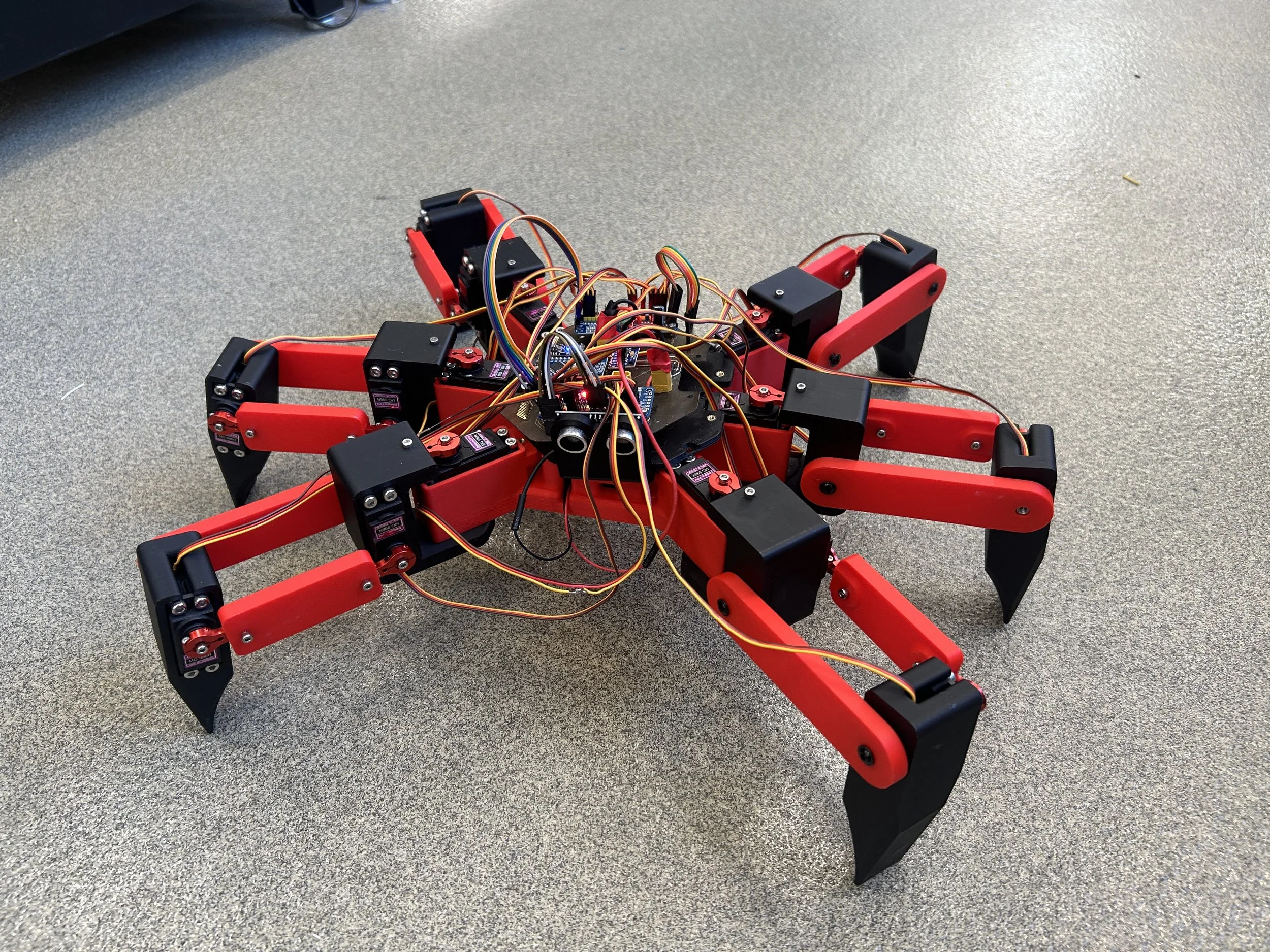

Worcester Polytechnic Institute’s Mechanical Engineering program has this lab-based class called Engineering Experimentation. It’s main focus is on microcontrollers and teaching students how to utilize devices like Raspberry Pi and Arduino. What the class also has is an open-ended final project where you work either by yourself or with a group partner to develop a product. Through this project, I decided to fully develop a 6-legged walking robot on my own.

A walker robot is a robot that utilizes 2-3 degrees of freedom per leg module to execute a walking motion for movement (think of how a crab or spider works)

A benefit of designing these robotic systems is that it greatly improves your sense for mechatronic based systems, your controls engineering skills, and your Design for Assembly skills due to how much electronics there are to factor

GIF Provided by roboticgizmos.com