Note: This is an ongoing project that will be updated as significant progress is made in the future

Project Overview

Since my freshman year at Worcester Polytechnic Institute, I have been a part of WPI’s Bionics team. Even though I am currently serving as the team’s Mechanical Lead, there have been multiple projects that I have worked on. My most major contribution to the team has been developing a 2-stage Planetary Gearbox for the elbow sub-team.

The planetary gearbox, and elbow sub-team as a whole, is one of many parts to make the team’s main project possible. This project is the designing, manufacturing, and assembling a prototype prosthetic arm. The goal of the arm is to replicate a human’s movements by receiving inputs from haptic sensors hooked up to a human’s arm.

The elbow sub-team has been tasked with developing a system that can hold up the lower arm portion of the arm, in which the hand is holding 2.5 kg of weight. This system would have to be both consistent and reliable, as the elbow is responsible for lifting a lot of weight.

Throughout the brainstorming period of this project, we utilized both torque calculations and team brainstorming techniques like mind-mapping. Ultimately, we decided on the gearing up a stepper motor’s torque using the planetary gearbox.

Here are some calculations and first versions of CAD designs.

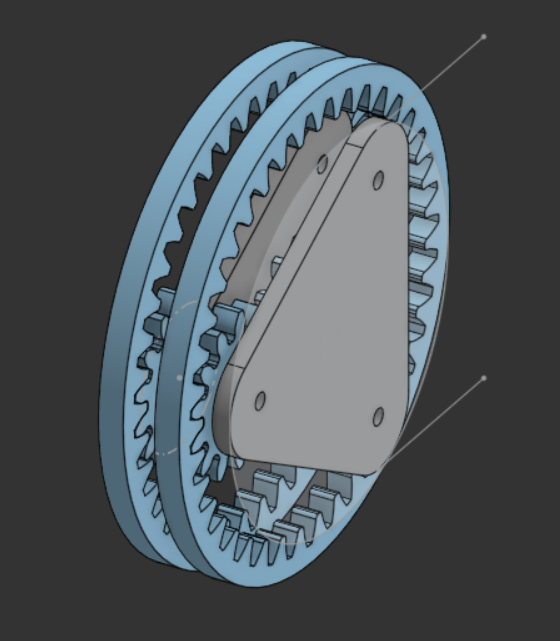

As I continued to develop the Gearbox, I completed a finalized first iteration of the design. Originally, the plan was to fabricate all gears, utilizing both CNC Manufacturing and water jet cutting. Each planet gear utilized ball bearings to rotate each planet gear’s shaft.

Here is the current state of the gearbox’s design. I made some heavy changes on both the thickness of the teeth, gear thickness, as well as the addition of a c clip system with 5 mm shafts and 5 mm ID bearings.